|

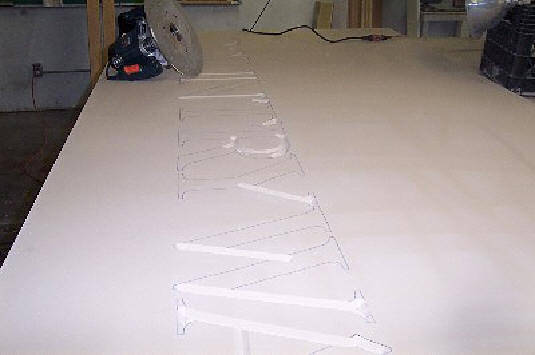

Step 1 First pen plot a pattern and transfer it to the hdu with carbon paper. I set the bit to a depth that will give me the narrowest lines. I rout

those. I then set it to the next wider lines and rout them. It's not that hard

to keep it straight, you just have to watch the pattern lines on both sides of

the bit at once. It's easier than it sounds. Just remember that if your router

is flat as long as you are within your pattern lines you are fine. Anytime your

letter starts getting narrower than your bit, just stop. I work my way up to

wider and wider parts until the bit is fully extended (if necessary) and then

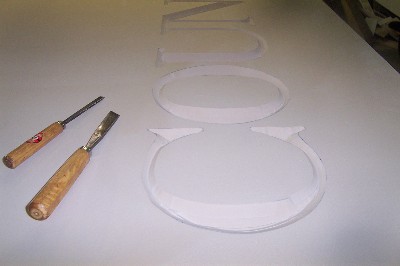

just hog out what you can with the router and get the rest with the chisels.

Back when I routed wood I would rout the square corners and not need to chisel

after. This was done by tipping the router on its base and pulling it up as you

went. Hdu is too easy to rout, there's not enough resistance to do this cleanly.

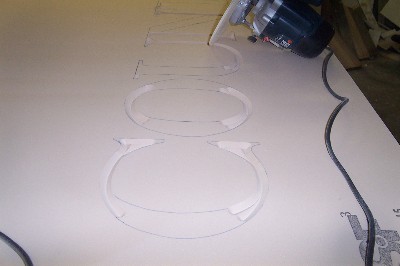

Concave routing with a 45 degree bit is a lot easier than flat routing and looks

a thousand times better. One time I had about 50 signs 2' x 8-12' to rout so I

made a jig that the blank was against a board at the back. I attached a board at

a right angle with a door hinge and routed all the up and down strokes. I then

made angled pieces of mdo to set against the board for the angle of the N's,

M's, A's, etc. It went pretty quickly.

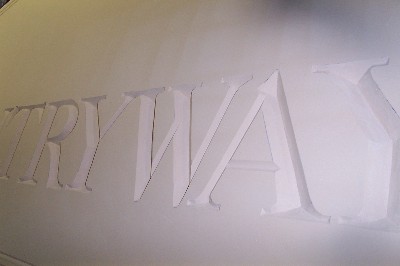

After blockout

|